As the world’s population continues to grow and urbanization accelerates, the demand for effective wastewater treatment has become increasingly crucial. Wastewater treatment plants play a vital role in protecting public health and the environment by treating and safely discharging wastewater. However, these facilities face numerous operational challenges that can impact their efficiency, compliance, and sustainability.

Companies like Ion Exchange are at the forefront of this field, offering state-of-the-art technologies and expertise to address the various operational challenges faced by wastewater treatment plants. This blog will explore these operational pain points and provide solutions to enhance the efficiency and reliability of wastewater treatment operations.

What is a Wastewater Treatment Plant?

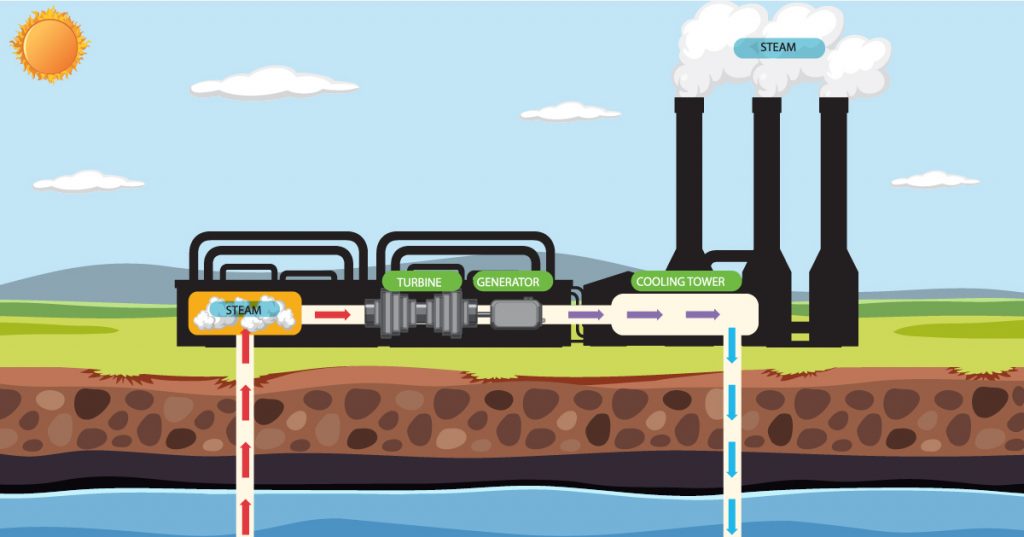

A wastewater treatment plant is a facility designed to remove contaminants from wastewater generated by domestic, commercial, and industrial sources. These plants use various physical, chemical, and biological processes to treat and purify the wastewater before discharging it into the environment or reusing it for non-potable purposes.

Common Operational Pain Points with Solutions

Wastewater treatment plants face various operational challenges that can impact their efficiency, cost-effectiveness, and environmental compliance. Here are some common pain points and potential solutions:

Predictive Maintenance and Smart Monitoring

Pain Point: Equipment maintenance and unexpected downtimes can significantly hinder the efficiency of a wastewater treatment plant.

Solution: Implementing predictive maintenance strategies and smart monitoring systems can help identify potential issues before they occur, allowing for proactive maintenance and reducing unplanned downtime.

Regulatory Compliance

Pain Point: Stringent regulations and discharge limits imposed by environmental agencies can be challenging to meet, and non-compliance can result in hefty fines and penalties.

Solution: Investing in advanced treatment technologies, real-time monitoring systems, and robust process control measures can help ensure consistent compliance with regulatory standards.

Energy-Efficient Practices

Pain Point: Wastewater treatment plants are energy-intensive facilities, with processes like aeration and pumping contributing significantly to operational costs and carbon footprints.

Solution: Adopting energy-efficient practices, such as process optimization, equipment upgrades, and renewable energy sources, can reduce energy consumption and associated costs while promoting sustainability.

Sludge Reduction and Valorization

Pain Point: Handling and disposing of large volumes of sludge generated during the treatment process can be costly and environmentally challenging.

Solution: Implementing sludge reduction strategies, such as advanced digestion techniques or co-treatment with other organic wastes, and exploring sludge valorization opportunities, like biogas production or land application, can minimize disposal costs and create value from waste.

Advanced Treatment Technologies

Pain Point: Conventional treatment processes may not be sufficient to meet increasingly stringent effluent quality standards or address emerging contaminants.

Solution: Adopting advanced treatment technologies, such as membrane filtration, advanced oxidation processes, or nutrient removal systems, can enhance treatment capabilities and ensure consistent compliance with effluent quality requirements.

Process Automation and Control

Pain Point: Manual operation and control of treatment processes can be labor-intensive, prone to human error, and may result in inconsistent performance.

Solution: Implementing automated control systems and supervisory control and data acquisition (SCADA) technologies can optimize process performance, improve efficiency, and reduce the risk of operational errors.

Training and Workforce Development

Pain Point: Wastewater treatment plants often face challenges in attracting and retaining skilled operators, leading to knowledge gaps and operational inefficiencies.

Solution: Investing in comprehensive training programs, apprenticeships, and workforce development initiatives can build a skilled and knowledgeable workforce, ensuring efficient and effective plant operations.

Ion Exchange: State-of-the-art Wastewater Treatment Plants Manufacturers

Ion Exchange, a pioneer in water and environmental solutions, has been at the forefront of addressing the operational challenges faced by wastewater treatment plants. With a deep understanding of the industry’s pain points and a commitment to innovation, Ion Exchange offers state-of-the-art wastewater treatment plants and customized solutions to meet the unique needs of each facility.

Our wastewater treatment plant solutions offer wide applications and pioneer innovations in water management by recycling wastewater and reducing its source. Our integrated systems focus on waste management through product recovery and waste minimization, employing energy-efficient and cost-effective membrane technologies, advanced oxidation, and evaporation processes. These technologies conserve water by recycling wastewater and recovering valuable products for reuse, achieving zero liquid discharge objectives.

This not only provides our customers with a strong return on investment but also protects the environment. After conducting bench-scale and pilot plant studies and detailed site surveys, we select the most appropriate technologies and treatment schemes. Our designs cater to various industries, including power plants, fertilizers, electronics, electroplating, textiles, chemicals, food and beverage, pulp and paper, pharmaceuticals, and automobiles, ensuring optimal recovery and reuse of water and products.

Explore Ion Exchange’s Products

Ion Exchange’s comprehensive product line for wastewater treatment includes the following:

WASTEWATER SYSTEMS

Ion Exchange’s wastewater treatment systems are designed to produce environmentally safe treated effluent and solid waste (sludge) suitable for disposal or reuse as fertilizer. Our pioneering solutions encompass water management through wastewater recycling, source reduction, product recovery, and waste minimization. The treatment process, comprising primary, secondary, and tertiary stages, is tailored to the wastewater characteristics and desired effluent quality. Our product range includes INDION® TADOX® (Advanced Photocatalytic Oxidation Process), High Rate Solid Contact Clarifiers, Anaerobic and Aerobic Systems, Membrane Bio Reactors, Packaged Sewage Treatment Plants, Packaged Waste Treatment Systems, Disinfection Systems, Odor Control Systems, Oil Screening and Grease Removal Systems.

WATER RECYCLE

Ion Exchange offers a comprehensive range of advanced wastewater treatment technologies, including continuous media filters, advanced oxidation systems, and membrane systems. The continuous media filters provide efficient solids removal, while the advanced oxidation systems employ powerful oxidants like ozone and hydrogen peroxide for the degradation of persistent organic pollutants. Additionally, membrane systems, such as ultrafiltration and reverse osmosis, enable superior separation and purification of treated effluents, ensuring high-quality water for safe discharge or reuse applications.

ZERO LIQUID DISCHARGE (ZLD)

With over 60 years of proven expertise, Ion Exchange incorporates advanced effluent treatment processes, innovative membrane technologies, and state-of-the-art evaporation processes to maximize water recovery and achieve zero liquid discharge. Our solutions offer assured availability of water for process needs and low-end uses, savings through the recovery of valuable products for reuse, reduced water costs and freshwater requirements, and assured compliance with pollution control board regulations.

Future of Evolving Water Treatment Technologies

As environmental regulations become more stringent and the demand for sustainable wastewater management practices increases, the water treatment industry is continuously evolving to develop innovative solutions. Emerging technologies, such as forward osmosis, electrochemical water treatment, and advanced bioreactors, are set to revolutionize the industry.

Connect with our wastewater treatment experts today to learn more about our comprehensive range of wastewater treatment technologies and services.